The material standard for such thickness pipes has no limitations you could ask sch 40 stainless steel pipe like astm a312 grade 316l.

Sch 40s schedule 40 stainless steel pipe dimensions.

Schedule 40 and 80 steel pipe as the common sizes that required in different industries because of the generally pressure these pipes bear they are always been asked for a large quantity.

The schedule number on pipe products relates to the thickness of.

Api 5l steel grades.

316 stainless stee l pipe has excellent corrosion resistance.

Fluid flow table of contents hydraulic and pneumatic knowledge fluid power equipment.

Nps od schedule wall thickness id.

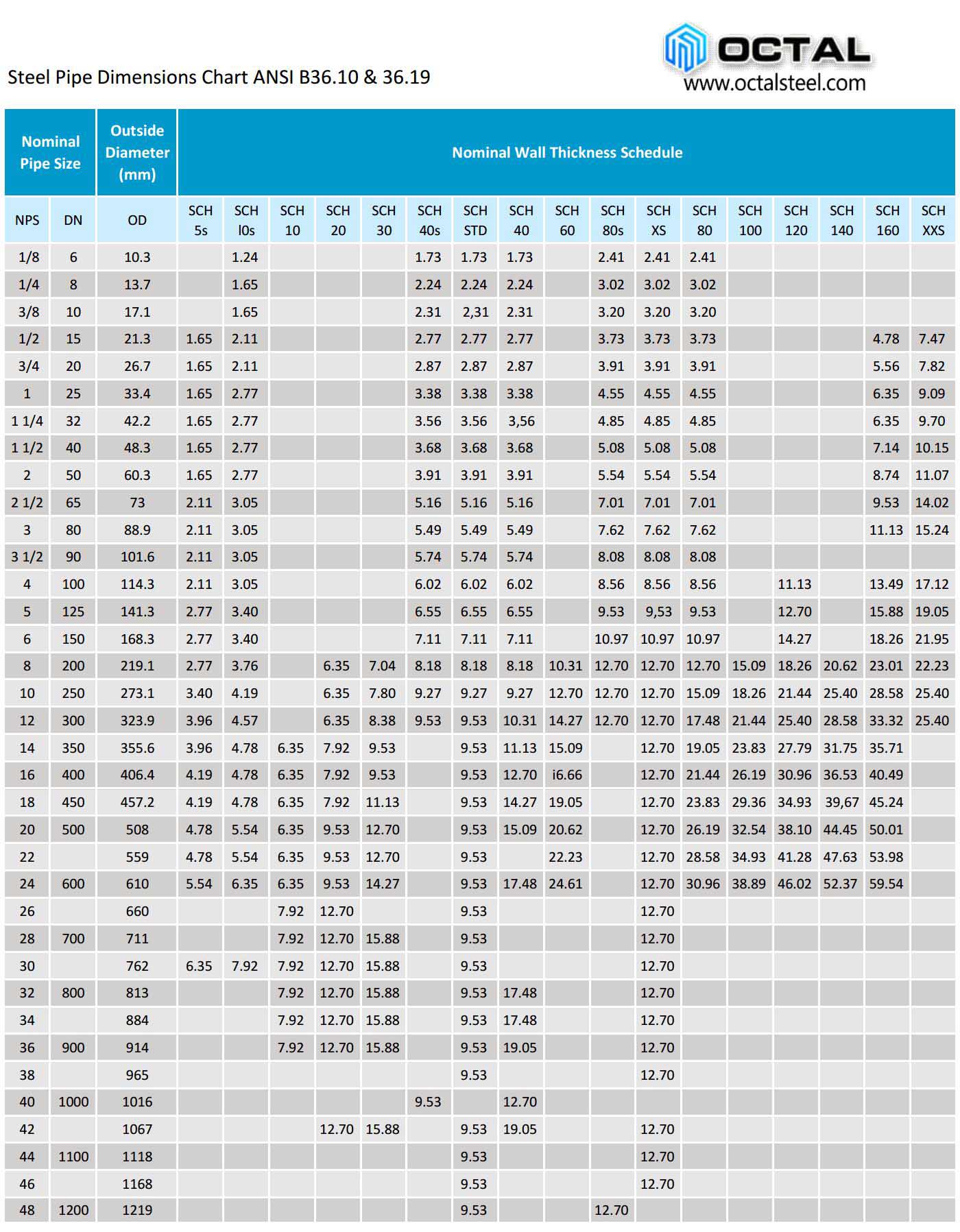

Schedule 40 steel pipe sizes dimensions asme ansi b36 10 19.

304 stainless steel pipe has very good corrosion resistance.

40 80 10s 40s.

Browse stainless steel pipe type 316l schedule 40s in the continental steel tube co.

Stainless steel schedule no.

Schedule 40 stainless steel pipe dimensions.

What do pipe schedules mean.

Wall thickness and weight.

Steel pipes schedule 40 chart.

Stainless steel pipe chart visit us at http www jpsteel us identification pipe size steel inches outside diameter inches iron pipe size schedule no.

What are pipe schedules.

Also known as schedule 40 this pipe has a thicker wall than our thin wall stainless steel unthreaded pipe.

Wall thickness t inches inside diameter d inches 1 80 405.

This chart gives dimensional size data for american national standard schedule 40 welded and seamless steel pipe.

Schedule 40 stainless steel pipe suppliers in india seamless schedule 40s pipe weight dimensions pressure rating of schedule 40 stainless steel pipe ss sch 40s pipe price 630 ton.

40 80 10s 40s 80s 049 068 095 307 269 215 1 40 540.

En 10220 european tubes.

Astm a270 sanitary tubing.

Or sch 40 carbon.

Nominal size pipe schedule outside diameter in wall thickness in pipe length m pipe weight kg.

Catalog including item size o d wall thickness weight.

Weld it to fittings and additional lengths of pipe.

Dimensions weight and thickness of stainless steel sch 40 pipes.

Welded connections are stronger than threaded connections and less likely to leak.